A bicycle derailleur is a toggle-operated mechanism that allows cyclists to shift their chains from one sprocket to another. It helps them modulate their input, measured in terms of pedaling effort, in order to generate maximum output, measured in terms of distance covered or speed gained.

The global advent of the pandemic has forced us to rethink our lifestyles in many ways. As people focus more on improving their health, the enjoyment of sport has skyrocketed, and cycling is one of the most popular new hobbies. The abundance of opportunities available to anyone in the market to purchase a bike can be overwhelming. While the choice for most bicycles boils down to personal preference, the functioning principle of all multi-speed bicycles is the same.

Recommended Video for you:

Single- And Multi-speed Cycles

Single-speed cycles have a fixed gear ratio, whereas multi-speed cycles are capable of shifting gears, similar to what one might do in a car. Shifting gear helps equalize the effort expended by the rider, regardless of the terrain. It means that the rider can ride uphill without exerting himself too much or accelerate on flat ground more effectively.

Bicycle Derailleurs

When a cyclist pedals, the energy from their feet is transferred to the wheels by means of a chain stretched taut between two toothed wheels, known as sprockets. One of these sprockets is located right at the pedal, while the other is located at the rear wheel. In a single-speed bicycle, there is one sprocket each.

However, in multi-speed cycles, there may be more than one sprocket at each end. These sprockets are mounted coaxially in succession and are known as cassettes.

Depending on the riding condition, the cyclist will shift the chain between various sprockets. This change of sprockets is effected by a derailleur.

A bicycle may have either a front and rear derailleur, or a rear derailleur only.

Given that the chain is of a fixed length, it cannot stay in tension on all sprockets, owing to their varying sizes. The derailleur not only ensures that the chain shifts to various sprockets, but also takes up and releases slack as necessary, in order to keep the chain taut at all times.

How Does A Derailleur Work?

In terms of function, both front and rear derailleurs have the same principle. They guide the chain to a higher or lower sprocket by pushing it while pedaling. This pushing is assisted by specially shaped teeth, known as shift ramps, which help the chain rise/fall to another sprocket.

Rear Derailleur

Construction

The rear derailleur is positioned below the rear cassette and secured to the bicycle chassis by means of a bracket. It consists of a spring-loaded linkage mechanism known as the parallelogram. Connected to this linkage is a ‘cage’ that houses two pulleys. The upper pulley, known as the guide pulley, drives the chain into the sprockets. The lower pulley, known as the tensioner pulley, takes up chain slack to ensure that it’s stretched tight between the driving and driven sprockets.

Working

The entire mechanism is actuated by a cable connected to a shifting toggle. When the cyclist presses a toggle, the cable tightens or slackens and stays in place. This forces the derailleur parallelogram to contort along it diagonal axis, moving the cage along with it. As the cage moves, it brings the guide pulley directly below the selected sprocket. It also pivots around its mounting point to accommodate for the increased or reduced slack in the chain.

When a cyclist goes to a higher gear setting, the chain travels outwards onto smaller sprockets. This change is brought about by the derailleur moving outward and downward. The chain slackens, which is adjusted by the tensioner pulley moving towards the guide pulley.

Conversely, when going to lower gear settings, the chain shifts onto the bigger sprockets. The derailleur moves inwards and upwards, with the guide pulley coming directly under the selected sprocket. As the slack reduces, the tensioner pulley moves away from the guide pulley.

Indexing

The amount by which the derailleur moves upon cable toggling is determined by a process called indexing. This is extremely important, as it enables seamless shifting. An improperly indexed derailleur can cause the chain to either fall between sprockets or drive crooked, both of which cause damage. Movement of the derailleur into extremities is further prevented by the use of limit screws.

Front Derailleur

Construction

The front derailleur is located directly above the biggest front sprocket. It is composed of a cage that directly connects to the respective parallelogram linkage. It serves to guide the chain as it rises or falls through various chain rings.

Since extra chain slack is taken care of by the tensioner pulley located at the rear, the front derailleur has fewer parts and a simpler construction.

Working

The front derailleur is identical to the rear derailleur in its function. However, the sprocket arrangement in the front is opposite to the rear, causing the chain to ‘rise’ from the innermost sprocket to the outermost sprocket. Indexing and the use of limit screws prevent the derailleur from moving to the extremes.

When Does A Cyclist Shift?

It is futile to understand the role of derailleurs without knowing when they come into action.

Shifting gears on a bicycle is a trade-off between efforts expended and distance covered. On flat surfaces, cyclists shift to the highest gears, which correspond to the smallest sprocket in the cassettes. This causes the pedaling to ‘tighten’ up, resulting in greater effort. This is useful, as it enables the cyclist to accelerate and cover greater distances in shorter spans of time.

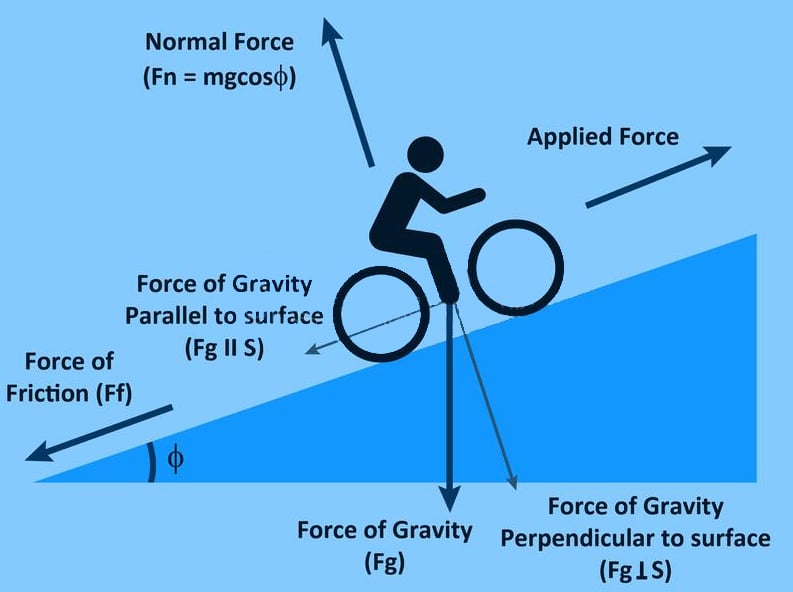

While riding uphill, the lowest gears corresponding to the biggest sprockets are preferred. This is because the cyclist has to work against gravity, which seeks to pull him downhill, in addition to other forces. A lower gear setting enables the cyclist to conserve energy by expending less force while pedaling. This is experienced as a ‘loosening’ of the pedals, but is accompanied by significant reduction in distance covered by the same amount of pedaling. Cyclists seek to improve their core strength to be able to cycle upwards in a higher gear setting to get an edge over their competitors.

Advancements In Derailleur Technology

In order to reduce shift timings and protect the chain from engaging the wrong sprocket combinations that reduce its life, electric shifting technology is now being deployed on high-end cycles.

Electronic shifting can be both wired or wireless. Instead of cables routing to pinch bolts that tighten or loosen springs, there are stepper motors that move the cage by a predetermined amount, thereby helping the chain shift from sprocket to sprocket.

However, this technology is prohibitively expensive for use on anything less than professional cycles.