A suspension system comprises of displacement units that help isolate the occupants from road vibrations while maintaining control of the vehicle

Have you ever wondered why your bicycle isn’t as comfortable as your motorcycle or car? While a smaller constricted seat could be one of the reasons, the primary reason is that every imperfection on the road surface is clearly felt on a bicycle. However, a car or motorcycle will glide over such obstacles with relative ease.

Recommended Video for you:

What Is A Suspension?

The trick to gliding over road imperfections and contours lies in an important component of every vehicle, known as the suspension. This feature is made possible by means of springs attached beneath the vehicle that absorb most of the undulations of the road, without transferring them to the driver or passengers. These springs are part of a vehicle’s suspension system, which not only ensures rider comfort, but also improves vehicle handling by bringing the “bounce” of these springs to rest in a suitable manner.

Why Do Vehicles Need A Suspension?

A suspension system in a vehicle serves to isolate the occupants of a vehicle from the vibrations that arise due to traversing the contours of the road surface, while helping the driver remain in complete control.

In order to have maximum control of a vehicle, it is imperative to be in maximum contact with the traversed surface, which appears to be in contrast with the original purpose of suspension—isolation from the road surface. Thus, suspension systems are designed to achieve a trade-off between occupant comfort and ride handling.

Another frequently overlooked function of suspension systems is the absorption of shock loads to prevent any damage to the chassis to which they are connected.

Sprung And Unsprung Mass

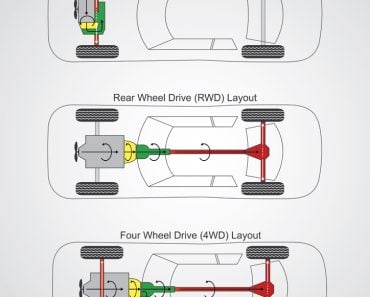

The part of the vehicle supported by the suspension system is known as the sprung mass. This usually includes various components, such as the driveline components, like the engine and transmission, vehicle body and chassis frame, as well as the passengers and their cargo.

The unsprung mass consists of the parts that are not supported by the suspension. These include the wheels, brake assemblies, differentials, drive axles etc.

In order to maximize control of a vehicle, a high sprung to unsprung mass ratio is desirable. A higher sprung mass ensures more force on the springs and wheels—and consequently, greater traction. However, there is only a certain extent to which the sprung mass of a vehicle can be increased without affecting handling and the adequacy of power produced by the engine. Thus, the sprung to unsprung mass ratio is a trade-off between traction and weight.

Components Of A Suspension System

A suspension system is made of the following components:

1. Links

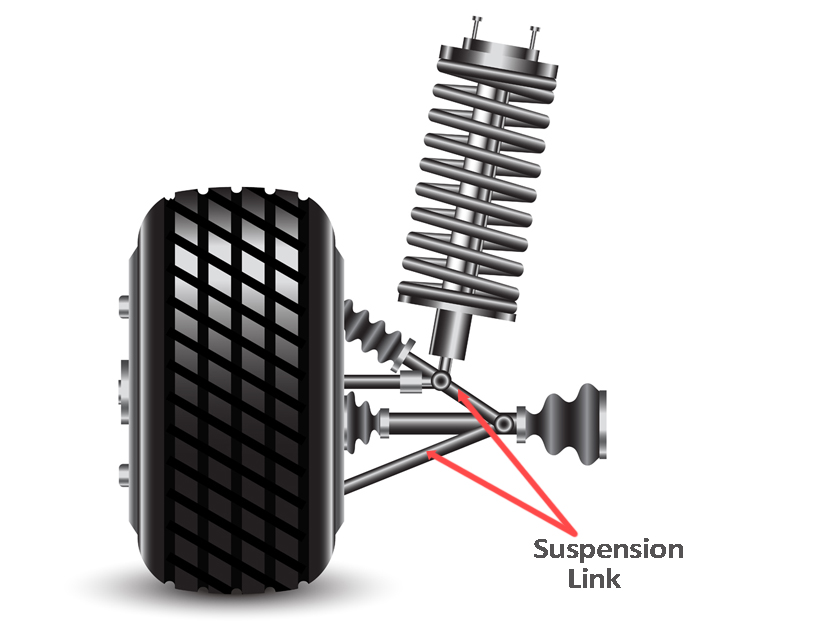

To allow for relative motion between the wheels and the frame, the suspension is connected to the chassis and the wheels by means of links. These links have various degrees of freedom, which define the axis along which the suspension moves.

2. Displacement Units

The displacement units are the core of any suspension system—the kinetic energy due to relative motion between the wheels and the remaining body when traveling over uneven surfaces gets stored in these displacement units.

While springs are a popular displacement unit, modern cars see hydraulic and pneumatic alternatives that can be electronically controlled. A displacement unit stores energy during travel over uneven surfaces and releases that energy when the wheels return to normal surfaces. The energy is released in a pattern known as damped simple harmonic motion.

3. Shock Absorbers (Dampers)

While a damped harmonic motion of the displacement unit can bring the vehicle to rest on its own, the time taken is usually longer, and the energy dissipation can be unregulated, leading to uncomfortable rides and a loss of suitable contact with the road. To eliminate this, it’s important to dissipate the stored energy in the displacement unit quickly and in a more regulated fashion. This is achieved by means of dampers.

A damper is composed of a piston head with holes in it traveling through an oil-filled cylinder. The incompressible nature of oil causes the piston to move slowly and uniformly through the cylinder, while ‘settling’ the motion of the displacement unit faster.

How Does Suspension Work?

The displacement unit in a suspension is capable of compression and elongation, based on the direction of wheel travel. When a wheel travels over a positive undulation on the road, such as a speed breaker, the displacement unit compresses. Similarly, when the wheel travels over a negative undulation, such as a pothole, the displacement unit elongates.

The kinetic energy due to wheel travel is stored in the displacement unit. A shock absorber is composed of a piston moving in an oil-filled chamber. This piston moves in synchronization with the displacement unit. Due to the incompressible nature of liquids, the piston movement is very restrictive and regulated, thus allowing for a controlled dissipation of the kinetic energy.

What Are The Various Types Of Suspension?

Suspensions can broadly be classified into two categories: Active and Passive. Passive suspension systems interact with the road based on their own configuration, whereas the configuration of active suspension systems can be electronically controlled based on user preferences.

1. Passive Suspension

I. Coil Springs

The displacement unit is a coil spring made of steel. These are a very cost-effective option and are found on most modern cars and motorcycles.

Ii. Leaf Springs

The displacement unit is a stack of elastic sheets of metal laid out laterally or longitudinally. While they were extensively used in old cars, as well as trucks and heavy load-bearing vehicles, they are now considered antiquated and rarely seen.

2. Active Suspension:

I. Air Springs

In this type of suspension setup, the displacement unit is an air-filled rubber bladder that can be inflated or deflated at will. This is generally accompanied by a compressor unit and a filter to prevent moisture from entering the system. Air suspension is better than mechanical suspensions in terms of ride quality, load-bearing and ride handling. However, these systems are more expensive to install and maintain.

Ii. Hydropneumatic Suspension

A hydropneumatic suspension is a combination of air springs and hydraulic damping integrated into one unit. Apart from damping, the hydraulic column also serves to vary the ground clearance by adjusting the ride height.

Advancements In Suspension Technology: Adaptive Suspension

An adaptive suspension system consists of an active suspension system linked to cameras, sensors and the GPS system built into a vehicle. This enables the onboard computer to make adjustments to the suspension configuration in anticipation of the terrain to come, thereby ensuring smoother ride quality and better handling.

Ride height control is another feature found in hydropneumatic suspension systems. By changing the amount of oil in the hydraulic column, the height of the vehicle can be varied slightly. A lowered car is more stable and easier to handle, while a high-positioned car can effectively clear underbody obstacles, such as high speed breakers, surface undulations, or even water from flooding.

What Does A Suspension Mean To Us?

The suspension, unlike other powertrain components like the combustion engine and transmission, will not become antiquated with the advent of electric vehicles, as stability and comfort of the ride will always be an important aspect of automotive travel. Paying close attention to suspension parameters and upkeep can go a long way towards improving the overall health and performance of your vehicle!