Table of Contents (click to expand)

A helmet is a type of protective gear designed to self-destruct by absorbing impact forces, while keeping the rider’s head safe in the event of an accident.

As much as we love the feel of the wind rushing through our hair, motor authorities always seem unhappy about it… and with good reason!

The brain is the most important organ of our body and riding a bike invariably puts it in harm’s way.

Unlike other forms of outward physical damage, brain damage has severe repercussions that are long-term, if not irreversible. Thus, wearing protective gear on a bike can never be overemphasized enough.

Recommended Video for you:

What’s Inside Your Helmet?

A helmet is the first thing that comes to mind when thinking about motorcycle safety. While not an accident deterrent, it significantly reduces the damage that can be caused during an accident.

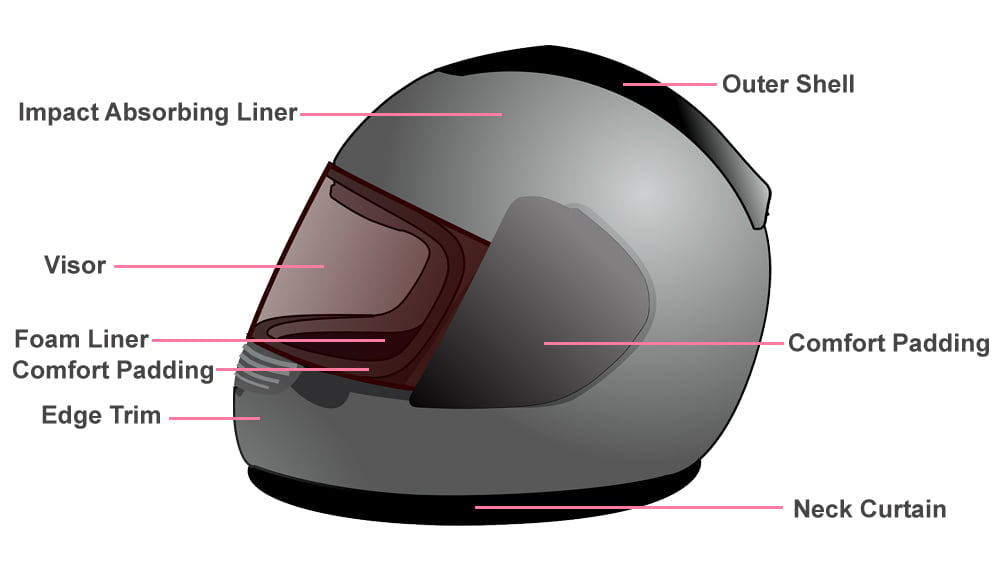

A helmet has several parts, each of which is engineered to offer comfort and aesthetic value, while giving paramount importance to safety.

1. Outer Shell

This is the visible and outermost portion of the helmet that forms its exoskeleton. While commonly available shells are made of polycarbonates, ABS and fibre glass-reinforced plastics, composites such as carbon fiber and Kevlar can also be used.

The outer shell is designed to crack slowly and exhibit abrasion resistance while sliding.

2. Impact-absorbing Liner

The impact-absorbing liner forms the core of the helmet. It is made of expanded polystyrene (EPS) that is capable of withstanding high shock and compression loads.

3. Foam Liner

The foam liner is a cushioning surface between the EPS liner and the rider. It is made of foam pads that snugly hold the rider’s head in place while wicking away moisture from sweat. A good foam liner does not allow any relative motion between the head and the helmet.

4. Retention System

A retention system is composed of straps that fasten under the neck to hold the helmet in place. They help secure the helmet to the head, to prevent it from coming off during impact.

5. Face Shield

Also known as visors, face shields cover the view port of the helmet, while still allowing the rider to see clearly. They are usually made of hard, shatter-proof polycarbonate. This prevents airborne debris from entering the helmet and damaging the rider’s eyes.

6. Ventilation System

Ventilation systems, though not a part of the primary safety system, is integral to it. Air circulation through the helmet not only keeps the rider comfortable, but also prevents the visor from fogging up due to moisture in their breath.

How Do Helmets Work?

In terms of physics, an accident is quantified as a large mass coming to rest within a gap of few milliseconds and millimeters of distance. The deceleration experienced by the body is several hundred Gs, with 1G being the gravitational pull of the earth.

The human body is clearly incapable of handling such intense shocks, some of which can result in fatal injuries. A well-engineered helmet has two lines of defense, namely the outer shell and the EPS liner.

During impact, the outer shell takes the first hit, and develops slow propagating cracks, reducing the amount of energy transmitted to the EPS liner. Since EPS is compressible, the major chunk of the residual forces is expended in compressing it. Consequently, very little energy is passed on to the rider’s head.

As per industry standards, a helmet that offers force penetration of less than 300G to the rider’s head is deemed roadworthy.

Testing And Certification Of Helmets

Unlike car crashes, motorcycle accidents cannot be simulated, due to the sheer number of unknown variables. However, manufacturers must adhere to standards that certify helmets as roadworthy. These standards get more stringent with time, thereby giving us progressively safer helmets.

Helmets are usually tested for both linear and rotational head movements. A head-form is fitted into the helmet’s receptacle where the rider’s head would go in. It is outfitted with sensors that measure impact at various points.

A typical roadworthy helmet is usually subjected to the following tests before it is made available for customers:

1. Impact Management

The impact resistance of a helmet is tested via various destructive tests, such as collision tests, drop tests and penetration tests. These tests are conducted by dropping the helmet at various velocities on anvils of different profiles. Impact resistance measures the integrity of the shell by its ability to develop slow propagating cracks and reduction of forces transmitted to the head form.

Another important test is the abrasion test, which involves sliding the helmet against tarmac. An easily sliding helmet will prevent twisting forces on the neck, thus preventing spine injuries.

2. Positional Stability

This non-destructive test is conducted to determine the tendency of the helmet to roll off the rider’s head during an impact. The helmet is suspended upside down at approximately 45 degrees to the normal and loaded at its edges. The load is orchestrated into a guided free fall and the elongation in the suspension mechanism is studied. If an elongation of more than 5mm is noted, the helmet is deemed unsafe, as it would roll off the rider’s head.

3. Retention Strength

In this test, the retention mechanism of the helmet is subjected to tensile loads to the point of failure. The retention mechanism of a roadworthy helmet is capable of withstanding shock loads of up to 400 kg. A helmet whose retention mechanism fails before the failure of its straps will come off in the event of a crash and is therefore unsafe for use on roads.

4. Area Of Coverage

A helmet’s design is a trade-off between maximum coverage and maximum visibility. Helmets are tested for good primary and peripheral fields of vision. A helmet with a narrow view port and restrictive peripheral vision, while affording more crash safety, cannot be used on the road. Similarly, incorporating a larger view port weakens the shell of the helmet, making it hazardous for use.

Commonly accepted helmet standards include US DOT, Europe’s ECE 22.05, Snell and SHARP.

With the evolution of composites and simulation techniques, the safety afforded to a rider by helmets is constantly increasing. Modern helmets also integrate wireless communication between them, thus increasing their utility. Nevertheless, the importance of wearing helmets cannot be stressed enough, whether you’re on a motorcycle, a bicycle, or anything in between!