All supersonic aircraft have pointed nose cones to reduce drag. Subsonic aircraft, on the other hand, have rounded nose cones.

Amongst all forms of transportation, the grandeur of aircraft is very hard to match. Even the fanciest sports cars come only remotely close to being as impressive as the flying machine. Within themselves, aircraft can be segregated into the cute, friendly neighborhood vehicles, or the stern, mean-looking ones you’d rather not be around. Wings loaded with missiles and fuel tanks, pointy noses and even fire-spewing tails! On the other hand, the cuter ones are passenger craft with round noses and tail cones that converge to a point.

Why are the nose cones sharp on one plane, while rounded on the other? Let’s dig in for some clarity.

Recommended Video for you:

Why Do Some Aircraft Have Pointy Noses While Others Don’t?

Simply put, the reason for the design variation is speed. Round nose cones are desirable for aircraft intended to be flown slower than the speed of sound. This is why commercial airlines, private planes, and recreational aircraft have round nose cones. Interestingly, not all military aircraft are meant to be flown at high speeds. This is why transport, surveillance and airborne radar aircraft also have round noses.

Such segregation is purely psychological. After all, aren’t the mean-looking aircraft invariably fighters? For fighter aircraft, speed is critical. With the sound barrier breached long ago, fighter aircraft that can travel at supersonic speeds are ubiquitous. Having a sharper, pointed nose cone greatly impacts the way air flows over them, letting them achieve such high speeds without much resistance. It is no surprise, then, that Concorde, the world’s first commercial airliner with supersonic capabilities had a pointy nose!

How Does Airflow Affect Nose Cone Geometry?

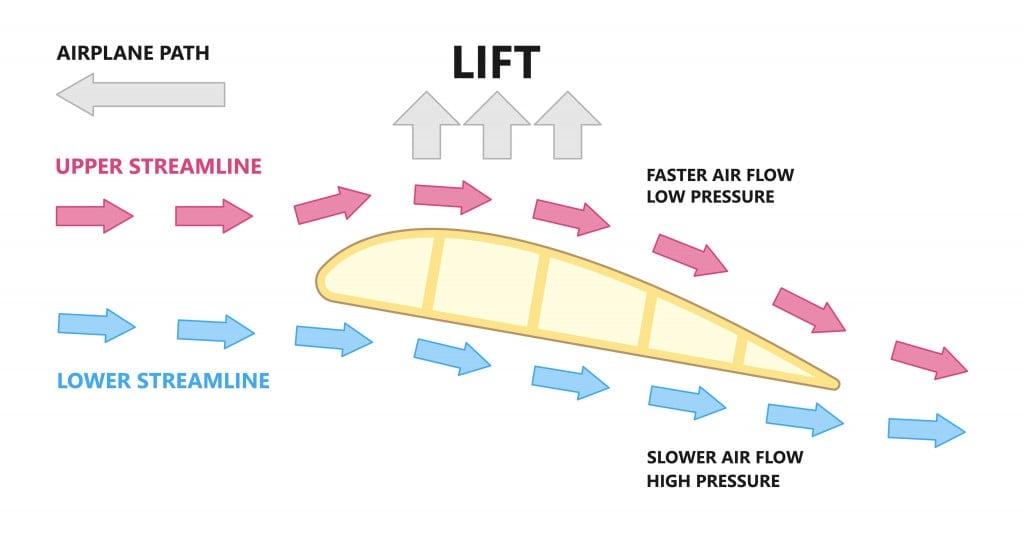

Airflow is the most crucial aspect of an airplane’s design. It helps to think of air as a viscous fluid medium through which planes fly. The particles of air resist the plane’s motion, a phenomenon known as drag. Drag has two components—the frictional component and the pressure component. The friction component is caused by the movement of air over the wing’s surface.

The pressure component, on the other hand, is caused by the shape of the aircraft and its body panels when they interact with air. The greater the drag, the greater the resistance to flight. This prevents aircraft from going at their intended speeds, while working the engines harder, thus consuming more fuel in the process. The nose cone is the first point of contact with air when it takes flight. It therefore ‘cuts’ through this medium of air, making way for the rest of the plane.

Rounded Nose Cones

Air particles at a given point move out of the way of an object flying at subsonic speeds, before it actually reaches that point. At subsonic speeds (less than 0.8 Mach), the pressure component of drag forces is 0 for all practical purposes. Having a round nose cone facilitates the gentle movement of air particles over and around it, while keeping frictional drag to a minimum.

Pointed Nose Cones

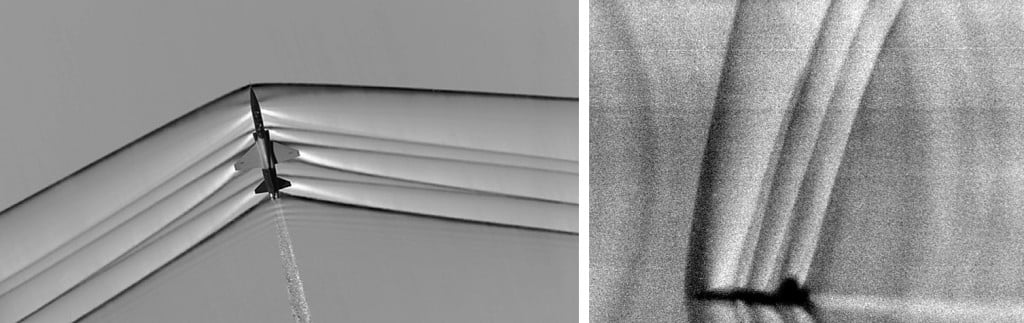

Air particles exhibit very different behavior when in contact with objects traveling at transonic speeds or greater. At such speeds, air particles at any given point have little to no time to move out of the way before the object reaches them. The result is a shock wave, leading to very high pressure at the aircraft’s nose, and low pressure behind it.

An object stuck between a high- and low-pressure zone tends to move into the low-pressure zone. Similarly, aircraft experiencing shock waves would be pushed into the low-pressure zone, or backwards, in their flight. Shock waves are generated at various points, such as the nose cone, tips of the wings and tail fins of an aircraft. Reduction in the surface area of these reduces the intensity of the shockwave, and consequently the drag. This allows them to travel at supersonic speeds—or even higher. This is why nose cones on fighter aircraft are pointed, in comparison to commercial airlines.

A Note On Friction Drag At Supersonic Speeds

At speeds greatly exceeding that of sound, it becomes necessary to make the nose cone rounder, rather than the ideal spear shape. This is known as bluffing, or blunting, of the nose cone. It can be either truncated slightly to a flat cross-section, or rounded off to a hemispherical tip.

This provides several benefits, the foremost being heat dissipation. Friction drag causes very high temperatures, which can actually melt the nose cone’s tip. Blunting it increases the surface area slightly, without increasing pressure drag, making it easy to lose heat. Other benefits include ease of manufacturing, safety in flight and while handling, and other advantages.

Are Rounded And Pointed Nose Cones The Only Profiles?

Loosely throwing around terms like “round” and “pointed” nose cones makes it easy to overlook the underlying engineering and design. In truth, the shape of various nose cones ascribed to different flying speeds are determined by mathematical equations. These mathematical equations yield a curve that generates a solid of revolution. The following visual succinctly explain a solid of revolution.

Thus, common nose cone shapes are solids of revolution generated by curves like parabolas, ogives, ellipses and even bi-cones. Interestingly, the most aerodynamic shape, a perfect cone, is actually not desirable for supersonic speeds.

Traditionally, nose cones have been designed around these geometric curves. However, modern designs rely on special mathematical equations devised for the reduction of drag.

Nose cone science and engineering is not restricted to aircraft. It plays an integral role in the design of projectiles like ammunition, missiles, vehicles like submarines and even space shuttles!

References (click to expand)

- Drag of Blunt Bodies and Streamlined Bodies. Princeton University

- M TOPTAŞ. Effects of Different Nose Cone Designs on Trajectory and .... dergipark.org.tr

- Ask Us - Rocket Nose Cones and Altitude - Aerospaceweb.org. aerospaceweb.org

- A Study on Airflow over a Plane - IJIRSET. ijirset.com

- NOSE CONE DESIGN AND ANALYSIS OF AN AVION. acadpubl.eu

- THE DESCRIPTIVE GEOMETRY OF NOSE CONES - UFPR. The Federal University of Paraná

- Rocket aerodynamics - Science Learning Hub. sciencelearn.org.nz

- Shock Waves - for How Things Fly. The Smithsonian Institution