In the rare event of engine failure, aircraft can be piloted to safety by reducing altitude and aggressively using flight controls.

Operating at roughly 35,000 feet above sea level, aviation is ironically the safest mode of transportation, considering that we are creatures not designed to fly.

Aviation industry history, however, is dotted with sporadic incidents, some of which end in near misses, while others result in catastrophe. One such scenario is aircraft engines failing in mid-air.

Recommended Video for you:

What Happens If Aircraft Engines Stop Working In Mid-air?

Unlike other potential dangers of flying, engine failure in flight is relatively frequent. However, this does not necessarily end in fatal crashes. It is helpful to understand its causes and the impact on both passengers and aircraft. While there are various types of aircraft engines, this discussion revolves primarily around the most common, twin-engine commercial aircraft.

Causes Of Aircraft Engines Failing Mid-air

Most commercial aircraft are powered by jet engines due to their superior design and reliability. However, these engines can fail due to both external and internal reasons.

1. Mechanical Failure

Any failure pertaining to the engine’s internal components is classifiable as a mechanical failure. Uncommon, but not unheard of in turbine engines, it is often traced to manufacturing defects or servicing errors.

Grave mechanical failures include fan blades detaching from compressors and turbines. This can then cause damage to other engine components and even the airframe. Other mechanical failures involve the leakage of combustible fluids, such as fuel and hydraulic oils.

2. Foreign Object Damage (FOD)

Turbine engines work well with only one thing – air. However, they can prove particularly fickle when accosted with any foreign object – birds, volcanic ash, or even tools or tiny spare parts that are missed during service.

At higher altitudes and in colder climates, ice can build up at the air inlet, causing damage to components downstream.

3. Fuel Starvation And Exhaustion

Choked fuel lines and pumping faults may prevent fuel from reaching the engine. Aviation fuel is susceptible to contamination that adversely affects its combustion characteristics. The engine may also be deprived of fuel in the case of complete fuel exhaustion.

4. Engine Stalling

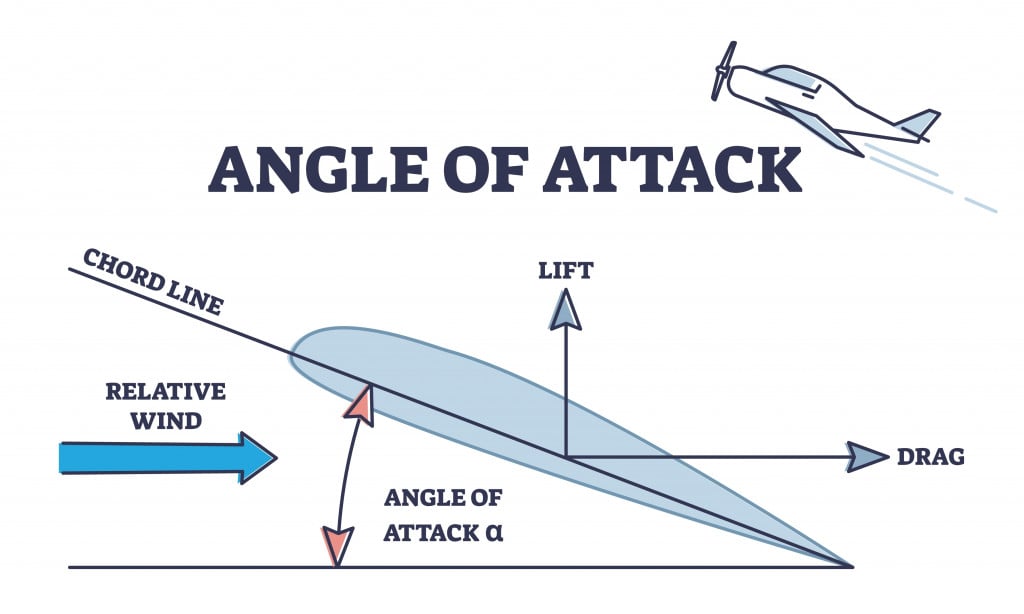

Aircraft engines, like car engines, are known to stall! However, stalling in aviation is very different to automobiles where engines stop turning, resulting in a loss of power.

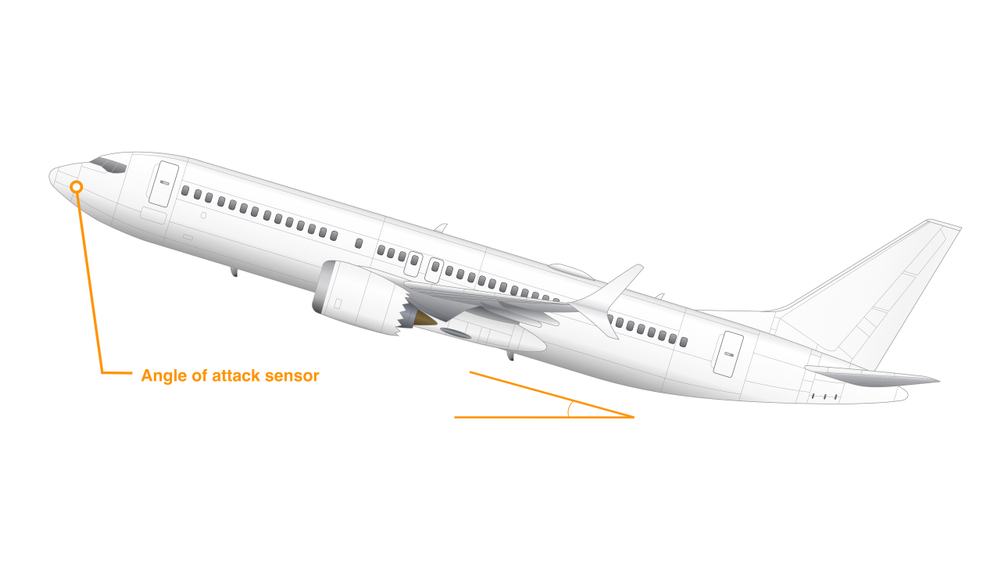

Aircraft often enter the wind at an angle, measured between its direction and inclination of the wing, known as the angle of attack (AOA). Beyond the critical AOA, there is insufficient airflow underneath the wings to sustain the aircraft’s lift, causing it to lose altitude very quickly.

Effects Of Engine Failure

Engine failure results in the loss of thrust, which is required for aircraft to maintain altitude or climb further. However, engine failure does not necessarily culminate into the complete loss of aircraft control. Aggressive use of flight controls, namely rudders and ailerons, can steer the flight to safety.

Aircraft compensate for a loss of thrust by losing altitude. They have a thrust-to-drag ratio of 10:1, which means they can fly 10 miles forward for every 1 mile lost in altitude. Cruising altitudes of 35,000 ft (~6 miles) give aircraft a distance of 60 miles to find a suitable place to conduct an emergency landing.

Engine failure is easier to deal with at higher altitudes than at lower altitudes, such as when taking off.

Landing With Engine Failure

Pilots faced with engine failure must conduct forced landings on the most favorable surface available to them. Here’s an interesting catch – this surface need not only be land. Airplanes can be ditched, i.e., landed on water or ice, without compromising passenger safety.

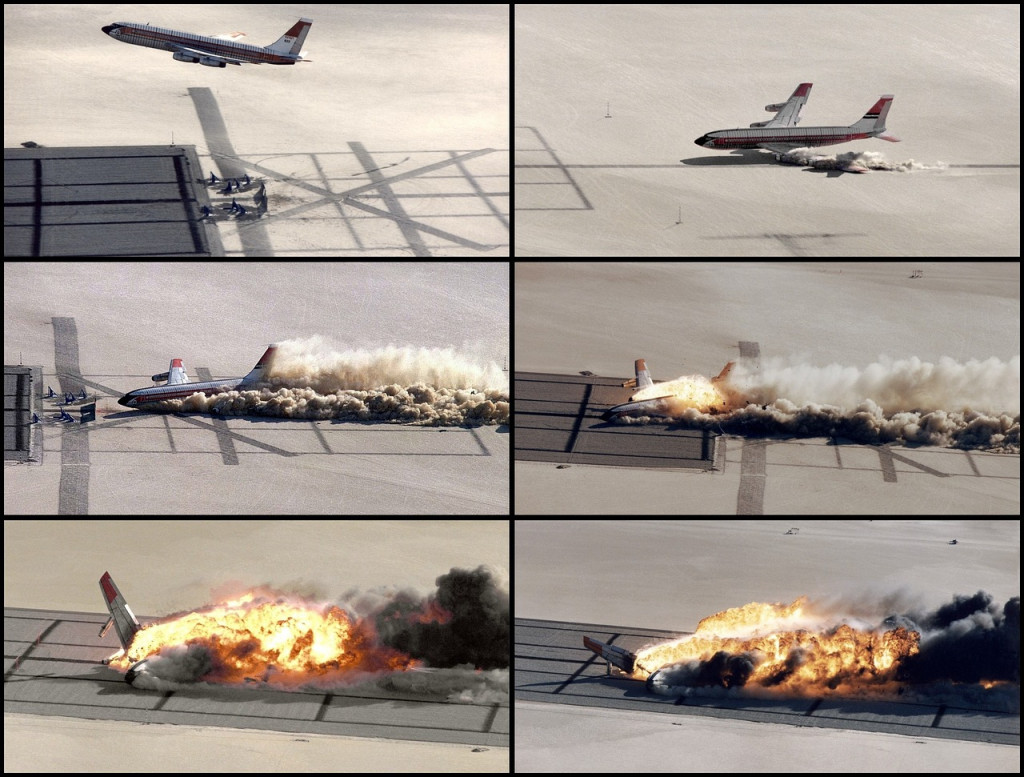

Similar to crumple zones in cars, aircraft have expendable parts in their structure to dissipate the force of landing in inclement terrain. These include the wings, landing gear, and even the bottom part of the fuselage.

Forced Landing From High Altitudes Due To Engine Failure

When landing from high altitudes, pilots have the benefit of distance to select suitable spots, and can ‘ease’ into the forced landing. Raising the nose cone to maintain altitude increases the risk of stalling, and thus a more rapid loss of altitude.

Pilots lower the nose cone, pulling the aircraft into a gentle glide and maneuver it with the flight controls available to them. It is desirable to land as flat as possible, to prevent the aircraft from cartwheeling or striking on the wing tips.

The pilots also cut off all power and fuel flow to the engine just before they touch down, to prevent the risk of fire.

Forced Landing Upon Takeoff Due To Engine Failure

Engine stalls and failures are very difficult to rectify at low altitudes. The first instinct it to turn back to the field from which the aircraft took off. However, it is important to achieve normal flying altitude before attempting to turn an aircraft around. Aircraft force-landing on airfields are safer due to the immediate availability of on-ground fire suppression systems.

Safety Measures To Prevent Engine Failure

1. Design

Mechanical failure can often result in components, such as blades, flinging out of the engine at high speeds, damaging other parts of the aircraft. To prevent this, engines are designed, tested and certified to contain such damage to within the engine’s nacelle.

2. ETOPS

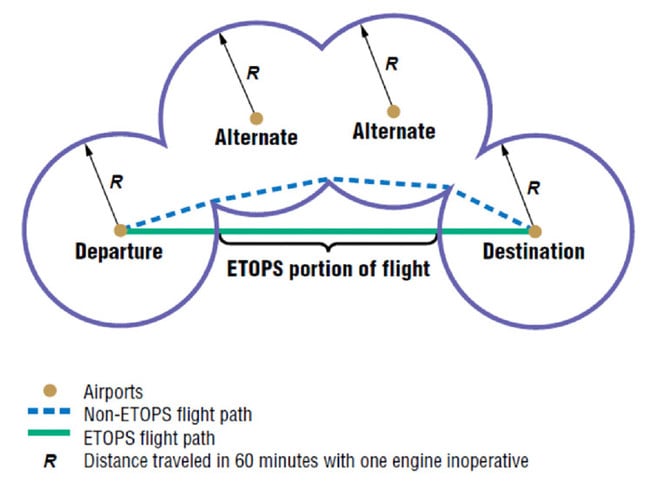

ETOPS, also known as Extended-range Twin-engine Operational Performance Standards, is a mandatory certification for airlines. It demonstrates their ability to fly commercial aircraft on one engine, if the other is inoperable, for a flying time of 60 minutes.

Given the minuscule probability of both engines failing simultaneously, this is considered adequate to find an airport for an emergency landing.

3. Fire Extinguishing Systems

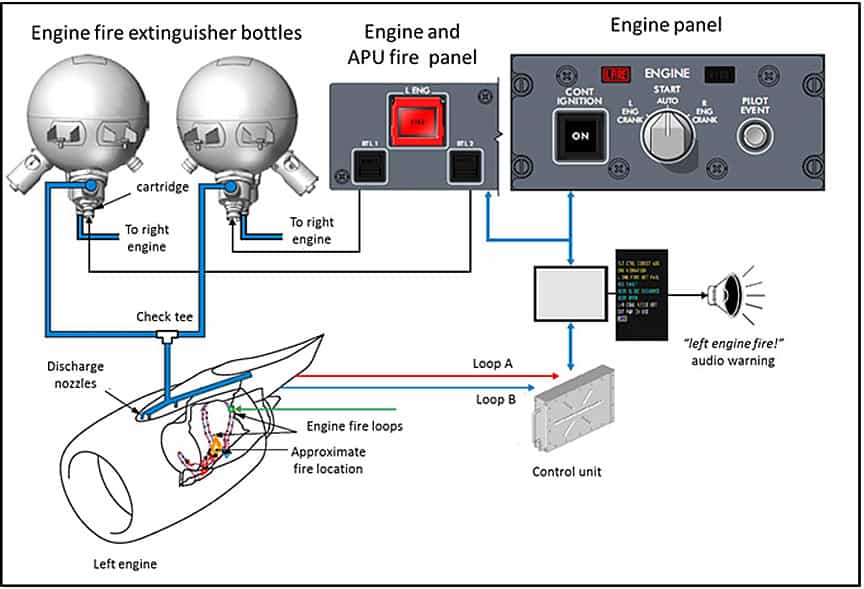

Aircraft are equipped with electronically operated fire extinguishers. If the engine catches fire, the fuel supply is staunched and extinguishers are deployed. This prevents the fire from engulfing other parts of the aircraft mid-air.

4. Engine Stall Rectification

Tipping the nose cone downwards helps reduce the angle of attack, preventing the risk of engine stall. Aircraft experiencing an engine stall will lose altitude much faster unless they take a gentler angle of attack, which allows them to glide.

5. Training For Engine Failure Prevention

Reducing human error during maintenance activities is a definitive way to prevent most aircraft engine failures. At the same time, pilots train rigorously for flying with failed engines to prepare for future eventualities.

Conclusion

Modern engines are extensively tested and equipped with sensors to map their health in real time. This is very helpful in mitigating mechanical failures and oversight due to human error.

Concurrently, flying safety protocols get stricter with time, further reducing the risk of engine failure due to pilot error. This goes a long way in ensuring flights remain the safest mode of transport available to us!

References (click to expand)

- Engine failure after take-off | aviation.govt.nz. Civil Aviation Authority of New Zealand

- AERO - The New FAA Etops Rule - Boeing. Boeing.com

- Airplane Flying Handbook (FAA-H-8083-3B) Chapter 17. FAA.gov

- Mastering the Maze of V-speeds - FAA Safety. faasafety.gov

- https://apps.dtic.mil/dtic/tr/fulltext/u2/a528013.pdf